Contents starts here.

Electronics Technology

Electronics technology designed in-house.

The best solution to suit your inspection needs.

By customizing the design specifications exactly, we meet a variety of complete inspection needs -from entrance to exit- regardless of material, field of inspection, or industry.

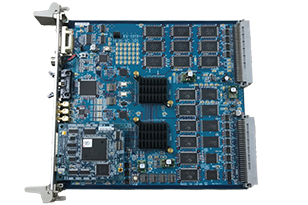

For example, we design our own boards, which are usually made from general-purpose products. This is an indication of our customer-first policy, that even in the unlikely event of an error, we are responsible for resolving it.

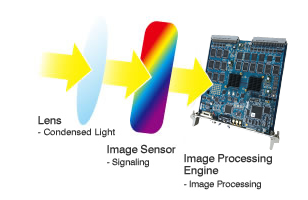

Proprietary image processing engine that is committed to high inspection accuracy.

For a digital imaging equipment, the image processing engine is the brain. It is no exaggeration that the judgment and processing speed of the engine greatly affects the inspection accuracy.

Digital camera device of us is capable of high-speed picture acquisition of more than 1,000 frames per minute maximum. It instantly analyzes the picture (charge) generated by the image sensor, determines the quality (judges), as well as transmits to reject device, and then compresses the image as an archive.

The image processing engine was developed in-house to reconstruct the work of this series, achieving both accuracy and speed.

With our original lighting board, image processing capabilities are maximized.

In order to maximize the capacity of image processing engine, the improvement of the inspection environment is essential. Our high-speed imaging greatly utilizes lighting to ensure accuracy. We continue to develop improvements in the inspection environment and lighting devices.

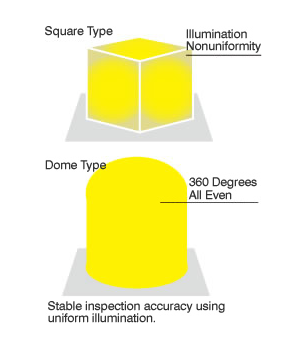

We solved the challenging task of developing uniform lighting. In the conventional mechanism, adjusting the light volume or changing the light supply could not suppress the occurrence of unevenness. This lead to reviewing of the lighting board design.

By changing one’s mindset from a square-shape to a dome-shaped arrangement of light sources, and after repeated trial and errors, we achieved the best light source arrangement. That’s the our original domeshaped illuminating device. We achieve clear imaging for optimum inspection by supplying a stable 4,000 to 9,000 Kelvin color temperature.

It is also equipped with the ability to automatically detect the deterioration of the light source and to adjust to compensate the amount of light using the power control.

Contents ends here.