Contents starts here.

Handling Technology

Gentle on products, tough on accuracy.

Technical capabilities to meet high-speed of diversified products.

Our technology create a smooth transfer, rotation, and ejecting of products. It takes the product from the line, conveys it into the machine, transfers it to the inspection station, accurately keeps it at the imaging position, and reliably ejects it from the line if it is detected.

Handling technology is a core technology that is essential to maximize the performance of the inspection machine.

The following draws attention to our handling technique for high-speed line support and diversification of products.

Technology that does not hinder the product in high-speed lines.

The Mouth Vacuum Suction Conveying System Speeding up the Preform Inspection (Patented)

When increasing the speed of the preform inspection’s transfer method, we accounted for the tendency of the neck guide to heat and cause the shaft to bend from the weight and pressure of the head at close contact to the preform. Our solution was the idea of sucking up the preforms without pressing the heads onto products with the Mouth Vacuum Suction Conveying System. With this technique, it became possible to stably convey the products at a super-high-speed of 1,300 BPM.

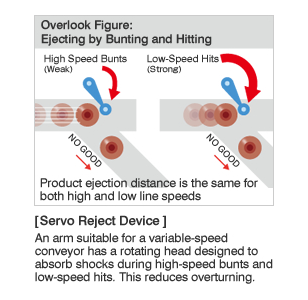

Servo Ejector System, Reducing the Load of Products During Unloading

With a faster inspection system, the reject unit needs to be fast as well. We developed a reject mechanism which tops its conventional High Speed Pusher.

This is the Servo-Type Reject System. The products conveyed in high-speed are led to reject section using an arm which controls the product flow line. Products in the line are lightly hit or bunted at high speed. To avoid toppled bottles, and to reduce the shock of hitting and bunting, a rotary head is used at the end of the arm . High-speed inspection goes to a new stage with the handling technology of us.

Technology to Hold the Various Products at the Bottom.

Bottom Vacuum Adhesion Method, to Hold Glass Bottles at the Bottom

When transporting the beverage containers, holding the products at the bottom, increases the simultaneous inspection by different units, a key necessity to the high-speed system. However, holding only the bottom is structurally unstable. Among containers, the heavy glass bottles are especially difficult to stably transport due to the characteristics of glass material.

We, experienced in glass bottle inspection, have our own handling technology. It uses a stable transport mechanism of bottom vacuum suction to hold the bottom of the glass bottle. This method allows for a variety of transport, from small drink bottles to sake bottles of 1.7 liter.

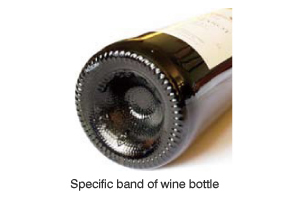

Furthermore, we have developed technology to support the bottom of wine bottles, which have punts (dents).

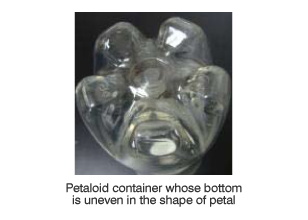

Also holds the petaloid bottom of plastic bottles used for carbonated beverages.

Plastic bottles for carbonated beverages have five petal-shaped irregularities, which is called “petaloid”. These types of bottles are specific for carbonated beverages. It is a special design that prevents ruptures by distributing the pressure of carbon dioxide in the bottle. The conventional bottom suction method was not able to handle these large gaps of petaloid bottoms. We developed a new structure to suck the bottle bottoms with dents using a suction cup built into the bottle base that moves up and down. This method makes it possible to apply suction to different bottom shapes of plastic bottles.

Contents ends here.