Contents starts here.

Optical Technology

Optical technology to master “seeing”.

Ribs, Specific of Plastic Bottles, Hide Foreign Matters.

Glass, plastic bottles, and cans… Inspection accuracy can be greatly influenced by the material and shape of the products. Opaque materials as with cans are not very easy to work with, even transparent materials can be challenging. We never stop researching on different cases.

As an example, we had this material research on plastic bottles. Our test showed foreign matter in liquid, big enough (3mm ) to be confirmed with a naked eye, that was sometimes missed by our machine vision. We found out, that the ribs, specific irregularities on plastic bottles, were causing this phenomenon as they were refracting the optical beam, that could be recognized with the naked eye.

Human Eye, the Ability to See in Three Dimensions.

Foreign matters in the liquid that are not detected by the camera right in front, can be detected from a different angle as the products are rotated in a rotary inspection system. But what happens in a straight system that does not rotate the products?

Straight type inspection machines are in high demand by plastic bottle beverage plants as they are fast, has short job change time, and has less trouble due to their simple structure. What can we do to convert the objects to stereoscopic images without loosing all the benefits of a straight line?

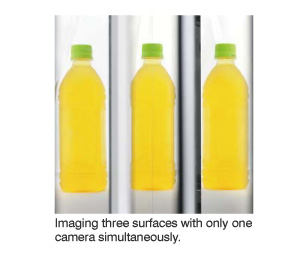

We proposed a mechanism with 9 digital eyes after repeated trials. This structure enables 9 simultaneous images using mirrors vaporized to the surfaces of three different cameras positioned in three levels.

That was the birth of a new mechanism which does not require rotating the plastic bottles, and also not receiving the influence of the ribs, adapting to the speed of straight lines (Patent pending).

Do you see the foreign matter in the orange juice?

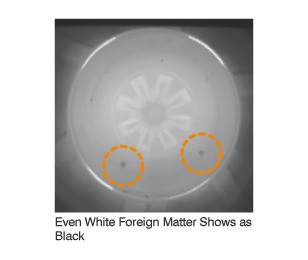

It has become common for the beverage content of plastic bottles are diversified from a high degree of transparency, such as tea and carbonated drinks, to low transparency beverages such as orange juice and lactic acid beverages. The low transparent beverages are referred to “diffusive liquids” in the inspection machine industry. These kind of beverages have low light transmittance liquids.

According to the inspection theory, infrared is used for these kind of liquids. But we have developed a more advanced technique that has optically high detective precision. With this method we can detect white foreign matter in white diffusive liquid, that can be easily noticed at a glance as a black substance in the image. By combining these technologies, we are able to detect any kind of foreign matter without being limited by the color of the liquid type, nor the color of the foreign matter.

Contents ends here.